Matter…for conception

Fabrice watched over the development of these mechanical arms over almost a year, plus the complete water scenography from start to finish.

We were approached by Phalsbourg, a company specialised in commercial real estate and with whom we had already worked on shopping centre projects such as “Ma Petite Madelaine” in Chambray-lès-Tours and “Waves Actisud” in Metz.

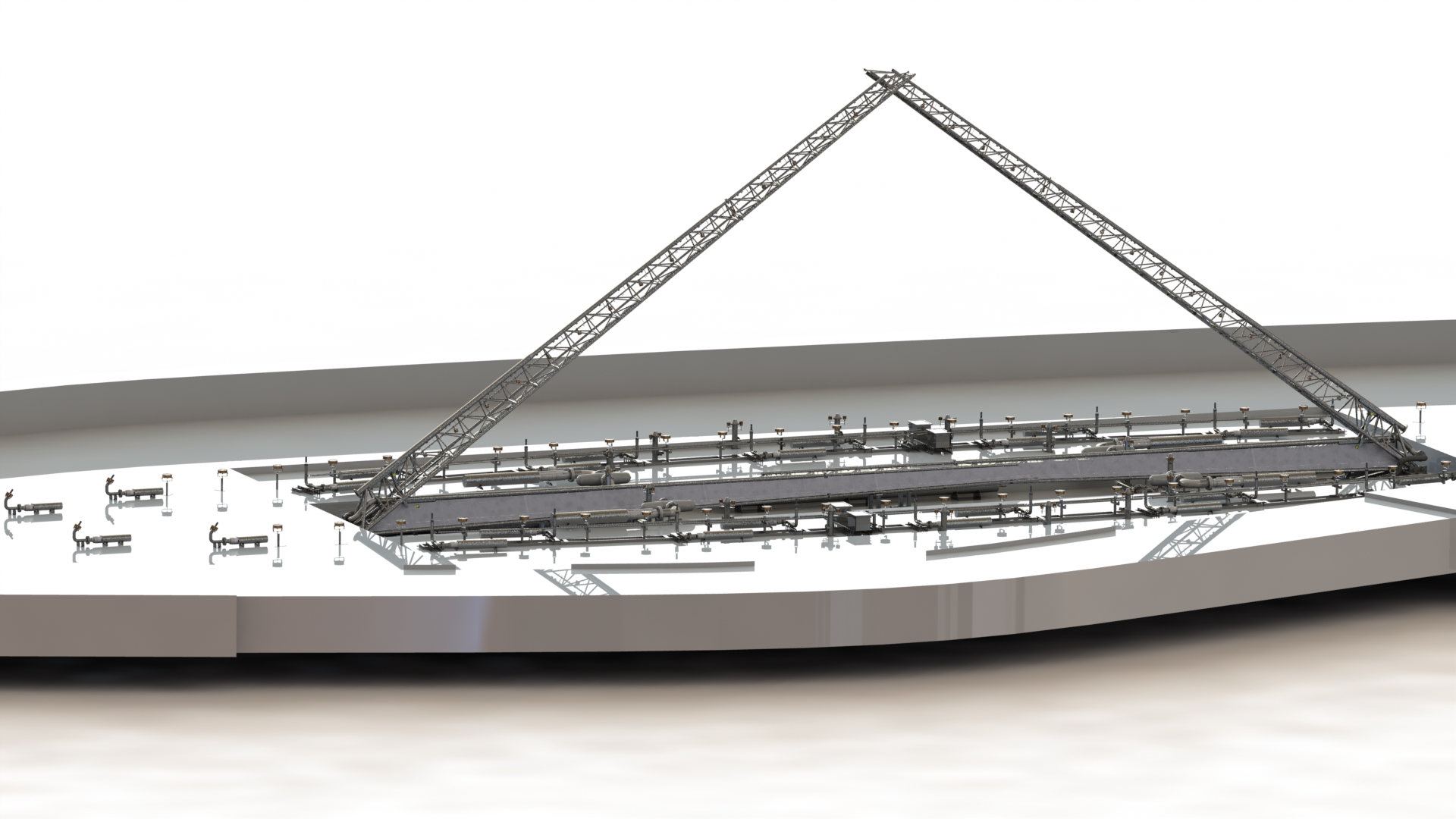

The idea was to create water shows for the artificial lake planned to be located in the heart of the shopping centre. With Michel Amann*, we thought about developing arms that would enable spectacular shows to be created on a regular basis with one being staged during the daytime and another at night.

This is in fact the 3rd mechanical arm Crystal Group has invented. The first was designed for the Futuroscope show “La Forge aux Etoiles” and the second for the Dubai CityWalk. This technology allows us to fully adapt our machinery to the project environment. For example, in Dubai, the arm is curved so as to follow the oval shape of the pool, whereas in Villefontaine both our arms are totally straight. We have the expertise to make these mechanisms and can adapt them to each project.

Can you give us a more specific description of these mechanical arms?

We have 2 arms 14 metres long made from a special type of stainless steel that never rusts. Different effects are mounted on these arms such as mist, led lighting, flames nearly 8 metres high and a water curtain that is deployed as the machinery rises up out of the water. When the pool is calm, our two arms are hidden away underwater in their enclosure. When the show starts, they rise up 35° in less than 40 seconds. During the day, a 4-minute musical show takes place every half hour. The arms rise up flooding the basin with mist and the water jets come to life.

In the evening, when darkness falls, the show changes: the LED lights come on, the water curtain comes to life animated by a video and the flames are impressive.

Everything starts in the design office when the machinery plans and diagrams are drawn up. It is important to have an overview of the project especially since we must also deal with the lake overflow (nearly 100 meters of overflow), water effects and setting up the technical areas.

Since the budget is an important factor, we made various proposals to our customer, each including a memo on energy costs. It is important to adapt to the constraints of the site. Even the staging is thought out in terms of what the site is capable of providing in terms of energy.

Once the project was approved, we designed the machinery at Crystal Group. The mechanical arms were located in front of our workshops and the first tests began.

Once the machinery was operational, transportation by truck to Villefontaine was organized.

How did the on-site installation go?

Our first on-site work started in February of this year. A dozen people took care of transportation, the crane and assembling the whole system. We had to take account of weather factors which delayed the filling of the pool and, as a result, the tests on our mechanical arms. When the water finally came to the artificial lake, we were able to schedule the shows and get ready for the inauguration scheduled for 17 May. Programming is an important stage in the life of such a project. The idea is that once the system is in place, our customer is left with an autonomous and lasting set of machinery.

The inauguration was a great success and today the shows run without any intervention needed. The mechanical arms rise up and fold away every day. We only go back to the site for maintenance which involves cleaning the filters and checking all the mechanics. We have also put a remote monitoring system in place. If the least incident happens, we know about it in real time.

*Michel Amann, Crystal Group Managing and Technical Director